- In 1839, Edmund Becquerel discovered the process of using sunlight to produce an electric current in a solid material, but it wasn't until a century later that scientists eventually learned that the photovoltaic effect caused certain materials to convert light energy into electrical energy.

- In the early 1950s, photovoltaic (PV) cells were developed as a spin-off, of transistor technology. Very thin layers of pure silicon are impregnated with tiny amounts of other elements. When exposed to sunlight, small amounts of electricity are produced. Originally this technology was a costly source of power for satellites but it has steadily come down in price, making it affordable to power homes and businesses.

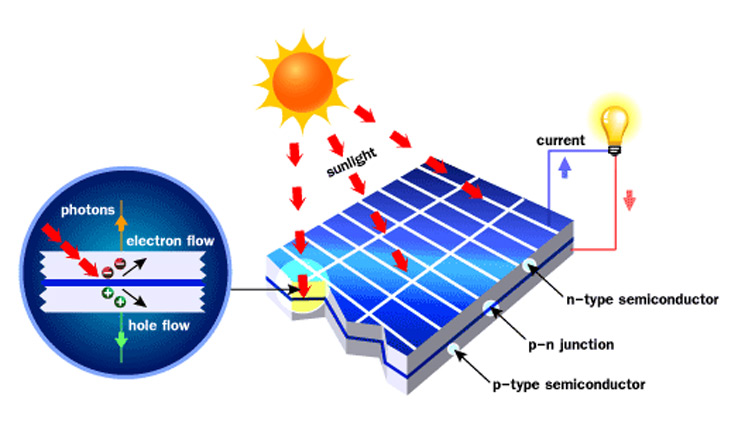

- The solar photovoltaic effect is the physical property that the irradiation in sunlight can stimulate the flow of electrons in a semiconductor material.

- A photovoltaic cell (PV cell) is a specialized semiconductor diode that converts visible light into direct current (DC). Some PV cells can also convert infrared (IR) or ultraviolet (UV) radiation into DC electricity. Solar cells, also called photovoltaic (PV) gets its name from the process of converting light (photons) to electricity (voltage), which is called the PV effect.

- Another way to understand is “A Solar Cell or Photovoltaic (PV) cell” is a device that is made up of semiconductor materials such as silicon, gallium arsenide and cadmium telluride, etc. that converts sunlight directly into electricity. When solar cells absorb sunlight, free electrons and holes are created at positive/negative junctions. If the positive and negative junctions of solar cell are connected to DC electrical equipment, current is delivered to operate the electrical equipment.

- Solar cells can be classified into first, second and third generation cells. The first generation cells—also called conventional, traditional or wafer-based cells—are made of crystalline silicon, the commercially predominant PV technology, that includes materials such as polysilicon and monocrystalline silicon. The 2nd generation cells are the thin film cells of cadmium telluride (CdTe), amorphous silicon (a-Si), while 3rd generation cells are advanced thin film cells and also adaptation of using multi-junction (MJ) technologies also used in space solar panels. MJ cells are usually compound semi-conductors and made of gallium arsenide and other semi-conductor materials. Most commonly used today are the crystalline silicon cells, which have withstood test of time over past 30 years of widespread use and reliability.

- A crystalline solar cell is developed from silica. After processing, it is made into ingots and bricks and sliced into wafer thin cells of original sizes of 100mm x 100mm, 125mmx125mm or round shapes. More commonly used sizes today are 156mm x 156mm square cells having thickness of 150 microns to 180 microns of either mono-crystalline silicon or multi-crystalline silicon.

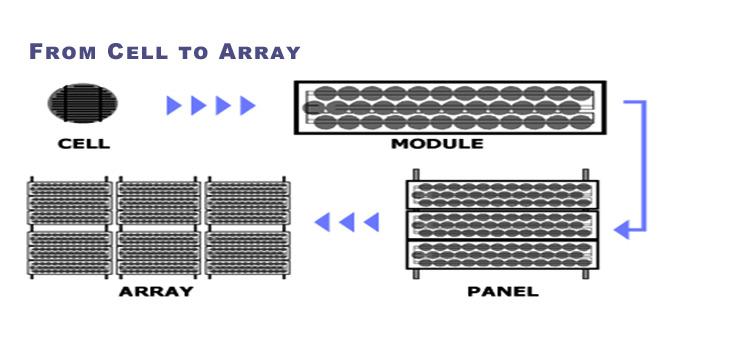

- A photovoltaic (PV) module is a packaged, connected assembly of typically 6×10 (60 cells) or 6x12 (72 cells) photovoltaic solar cells.

- A module’s electrical connection is made in series to achieve a desired output voltage and/or in parallel to provide a desired current capability. The conducting wires that take the current off the modules may contain silver, copper or other non-magnetic conductive [transition metals]. Bypass diodes may be incorporated or used externally, in case of partial module shading, to maximize the output of module sections still illuminated.

- Each PV module is rated by its DC output power under standard test conditions (STC), and typically ranges from 40 to 360 watts based on present efficiencies. A standard test condition is generally defined as DC output of solar PV module at 25 degree centigrade module temperature, under 1000 Watts / sqm of solar radiation and solar spectrum of Air Mass (AM) of 1.5.

- Depending on construction, photovoltaic modules can produce electricity from a range of frequencies of light, but usually cannot cover the entire solar range (specifically, ultraviolet, infrared and low or diffused light). Hence, much of the incident sunlight energy is wasted by solar modules, and they can give far higher efficiencies if illuminated with monochromatic light.

- Solar cell efficiency refers to the portion of energy in the form of sunlight that can be converted via photovoltaics into electricity. The efficiency of the solar cells used in a photovoltaic system, in combination with latitude and climate, determines the annual energy output of the photovoltaic system.

- A photovoltaic system, also called solar PV power system, or PV system, is a power system or array designed to supply usable solar power by means of photovoltaics.

- When sunlight strikes solar cell surface, the cell creates charge carrier as electrons and holes. The internal field produced by junction separates some of positive charges (holes) from negative charges (electrons). Holes are swept into positive or p-layer and electrons are swept into negative or n-layer. When a circuit is made, free electrons have to pass through the load to recombine with positive holes; current can be produced from the cells under illumination.

- The individual solar cells are connected together to make a module (called 'solar module' or 'PV module') to increase current and the modules are connected in an array (called 'solar array' or 'PV array'). Depending on current or voltage requirement, solar arrays are connected in a variety of ways:

- If the solar arrays are connected in parallel, the output current will increase.

- If the solar arrays are connected in series, the output voltage will increase.

- Firstly, the sunlight shines on "solar panels", which are usually mounted at inclination of latitude of the place which enables solar panels to face the sun for maximum period of the year and this creates DC (direct current) electricity. Each solar panel is usually a string of 60-72 solar cells “stringed” together in series on your roof. In the case of a system, these solar panels terminal ends (via cables) are connected to an inverter. The DC power will flow down to the inverter at which point the inverter will convert this electricity into AC (alternating current) power in the same voltage as is used in your house.

- The inverter feeds AC power to your circuit board and this power is available to service any electrical loads within your property. If the loads in your house are greater than the power that is being supplied by the inverter then your loads may be partly met by solar power and partly by the use of grid power. With gird-connect solar power systems you have the option at any time to use either solar power, grid power, or a combination of both. This benefits in savings of utility tariff you may be paying.

- In some instances you may be generating more solar power than your total electrical loads require and in this case your solar electricity will flow back out to the grid through your meter. Usually your utility meter needs to be changed so that it can keep a separate record of what electricity you export to the grid and what you consume from the grid. This process is generally called net metering or in some cases gross metering depending on type of method used to export and measure solar power. Various utilities have preferential or favorable tariffs for this process and more popular under solar rooftop grid tied systems.

- In other instances, if the utility does not permit export or prefers to receive such excess solar power at early morning or late evening or peak load times, generally with “time of use” or “time of day” concept with utilities favoring differential tariffs for load balancing, then newer options are there wherein energy is stored in high efficiency lithium batteries and this stored solar energy is released when load is peak on utility grid, thereby balancing the grid as well as providing user with rebate or tariff benefits for optimal use of solar power. Here the benefits again come from utility under energy storage systems or time of day use.

- Simplest instance for areas which do not have grid power or irregular supply of grid power in India, is to use solar energy to charge batteries, which are also called off-grid systems wherein stored solar energy during day time is used to power loads at different times over 24 hours at choice of user. Newer systems also provide hybrid options, wherein the above function as well as net metered function is performed by same inverter, but subject to local utility rules. Here the benefits come from having AC power for your homes during power cuts or un-availability or hybrid benefits including net metering benefits of utility.

- Electricity is instantaneous and we all know that the sun doesn't shine at night. What this means is that in a grid connect system you need to rely on grid power to service your electrical loads at night. In states with a 1:1 net metering policy for every kwh (kilowatt hours is a unit of measure for electricity) that you export during the day, you get a credit from your utility for the purchase of one kwh of electricity at night. This way, in states with a 1:1 "net metering policy" if you install a solar energy system that produces the same number of kwh's as you buy from your utility each year then you can get to a zero utility bill.

- Some states do not have 1 for 1 net metering policy. In these states often consumers with solar systems are paid only a fraction of the retail price for excess solar power that they export to the public utility grid during the day. In these states the availability of cheaper battery storage solutions which allow home owners with solar panels installed on their houses to store their excess daytime solar power for night time use, may make solar energy much more attractive. The newer solar on-line grid connected battery storage solution or “time of use solutions” by few companies has created a lot of excitement even if you do not have a good net metering policy.

- the solar panels, which forms about 55-60% of a project cost.

- solar inverters, which forms about 15-20% of a project cost.

- interconnecting cables, which forms about 3 to 5% of a project cost.

- control panel for DC and AC sides for protection, surge protection, lightning protection and earth and interconnection to grid which forms about 3 to 5% of a project cost.

- A Solar Photovoltaic system is installed by a user for residential or office or industry or commercial use for its lifetime of working which is generally 25 years.

- Thus while many firms offer initially low pricing, the lifecycle of the component will be lower depending on quality of products given as quality has a price.

- Thus to avoid recurring lifecycle expenses, recurring maintenance costs, poor warranty service are critical in making decisions of buying.

- A good design and engineering of system is also critical to determining system efficiency, proper working, safety, reliability, avoidance of accidents, meeting building codes and standards of utility, warranty cover of manufacturer (poor design voids warranty many times), and lifecycle costs of components used.

The most semiconductor material currently used for solar cell production is silicon, which has some advantages as; it can be easily found in nature, does not pollute, does not harm the environment and it can be easily melted, handled and formed into mono-crystalline or multi-crystalline silicon form, etc. The commonly used solar cell is configured as a large-area P-N junction made from silicon. There are three major cell types that are classified by its manufacturing technology and the semiconductor.

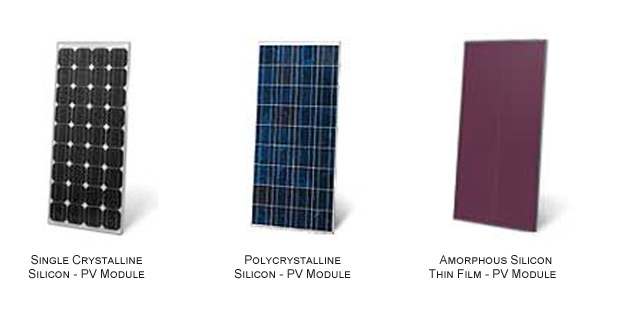

- 1. Crystalline Silicon PV Module : Two types of crystalline silicon (c-Si) are used to produce PV module; single crystalline silicon or known as monocrystalline silicon and multi-crystalline silicon, also called polycrystalline silicon. The polycrystalline silicon PV module has slightly lower conversion efficiency than single crystalline silicon PV module but both of them have high conversion efficiencies that average about 16-19%.

- Monocrystalline panels as the name suggests are created from a single continuous crystal structure. A monocrystalline panel can be identified from the solar cells which all appear as a single flat color.

Construction

They are made through the Czochralski method where a silicon crystal ‘seed’ is placed in a vat of molten silicon. The seed is then slowly drawn up with the molten silicon forming a solid crystal structure around the seed known as an ingot. The ingot of solid crystal silicon that is formed is then finely sliced to obtain, what is known as a silicon wafer. This is then made into a cell.

- Polycrystalline or Multi-crystalline vary in the manufacturing process.

Construction

Polycrystalline also start as a silicon crystal ‘seed’ placed in a vat of molten silicon. However, rather than draw the silicon crystal seed up as with monocrystalline the vat of silicon is simply allowed to cool. This is what forms the distinctive edges and grains in the solar cell.

- Monocrystalline panels as the name suggests are created from a single continuous crystal structure. A monocrystalline panel can be identified from the solar cells which all appear as a single flat color.

- 2. Amorphous Silicon PV Module : Amorphous silicon (a-Si) PV module or thin-film silicon PV module absorbs light more effectively than crystalline silicon PV module, so it can be made thinner. It suits for any applications that high efficiency is not required and low cost is important. The typical efficiency of amorphous silicon PV module is around 6 to 8%. A thin film panel can be identified as having a solid black appearance. There are other thin film technologies some of which are identified below.

Construction

Thin film panels are made by depositing a photovoltaic substance onto a solid surface like glass. The photovoltaic substance that is used varies and multiple combinations of substances have successfully and commercially been used. Examples of the most other common photovoltaic substances used are:

- a) Cadmium Teluride (CdTe)

- b) Copper Indium Gallium selenide (CIGS)

- c) Dye Sensitized Solar Cell (DSC)

- Number of cells in a module depends upon the standard voltage requirement per module. Nowadays 60 or 72 cell modules are manufactured having open circuit voltage Voc of about 37 to 44 Volts.

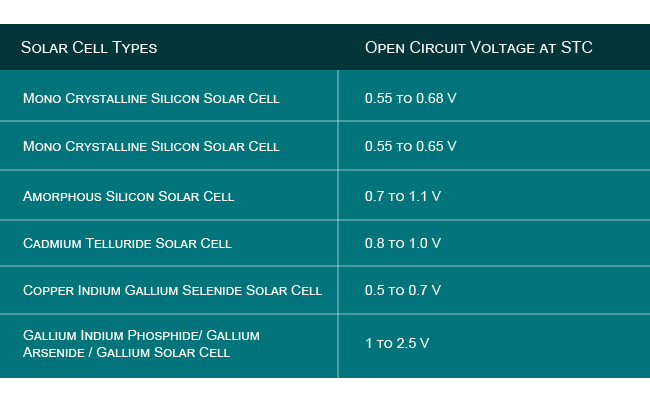

- Early in 1980’s solar modules were mainly manufactured for charging 12 Volt batteries. But for charging a 12 Volt battery it is required to have sufficiently higher output voltage of the module than 12 Volt. It was standard practice to design a solar module with maximum voltage rating, Vmp of 15 Volt. This module of 15 Volt becomes standard module from those days. The number of solar cells to be connected in series to achieve standard voltage output depends upon the open-circuit voltage (Voc) of the individual cells. The Voc of a solar cell depends upon mainly its manufacturing techniques. The table below shows the open-circuit voltage of different solar cells at standard test conditions.

- For a crystalline solar cell the open-circuit voltage, is about 0.5 V, as shown in the table above. The voltage Voc is mentioned at 25oC but at the temperature higher than 25oC the value of this voltage drops nearly by 0.08 V. So at normal operating temperature the voltage available across the terminals of each crystalline solar cell is 0.5 - 0.08 = 0.42V , Now, it is standard to make a solar module which can give 15 V open-circuit voltage at any condition. Hence, the required number of solar cells to construct such solar module is, 15 / 0.42 = 35.71 === 36 . So, 36 numbers of crystalline solar cells are required to build a standard solar module of 15 V max voltage.

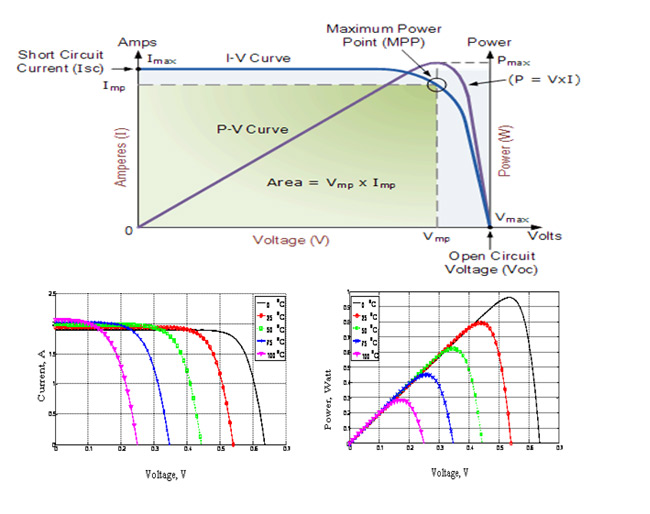

- The I-V curve is a Current-Voltage Curve of a Solar Panel, which defines the performance of solar panel under different conditions.

- The span of the solar cell I-V characteristics curve ranges from the short circuit current (Isc) at zero output volts, to zero current at the full open circuit voltage (Voc). Therefore the ideal operation of a photovoltaic cell (or panel) is defined to be at the maximum power point.

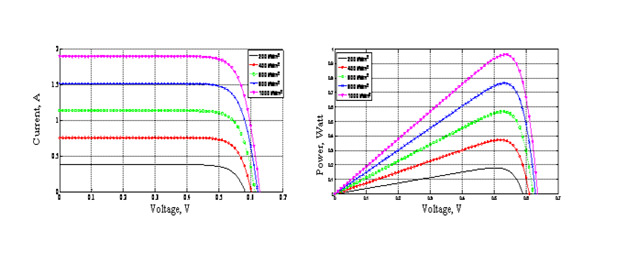

Performance of a solar panel under varying temperature conditions under constant irradiation.

Performance of a solar panel under varying irradiance conditions under constant temperature at 25 deg c.

Current and Voltage v/s Power and Voltage curves of a PV panel at different temperatures. Thus design of solar panel is very critical for obtaining best performance under given conditions of both irradiance and temperature apart from potential induced degradation, shunt and series resistance. The shunt resistance (Rsh) must be higher to avoid current loss at the junction diminishing the photocurrent and hence the solar cell performance. These parameters also enable crucially the selection of other components as inverter and cables.

- There are generally 2 types of inverters depending on type of use or mounting and conversion and operating efficiencies. Generally, they are only string inverters and micro inverters. Very large string inverters used in multi MW scale plants are sometimes called central inverters. But all inverters convert the Direct Current (DC) solar panels, and generate into an Alternating Current (AC), the type of electricity that is used in your homes or offices at single or 3 phase voltage of 220V or 440V.

- A standard inverter (also known as a string-inverter or central inverter) is a standalone unit that is typically installed close to your fuse box and electricity meter in residential or office use. There is typically only one, or possibly two, string inverters on each residential solar installation and multiples of these in a larger commercial or industrial installation.

- A string inverter functions in a series circuit with there usually being 6-21 individual solar panels in what is known as a "string" connected depending on individual solar panel voltage rating to optimize maximum power of that "string”.

- Micro-inverters perform the same basic function but are installed underneath each panel on your roof. Each of these micro-inverters is about the size of an internet router. The big difference is that a solar panel installation with micro inverters will have the same number of micro inverters as there are solar panels.

- A micro-inverter functions in a parallel circuit. To simply put, a string inverter will cap the electricity production of each panel by the lowest producing panel of all the panels (6 to 21) on the “string” on your roof. A micro-inverter on the other hand, will take full advantage of the production of each individual panel. It will convert the power generated by each panel to the grid voltage at its maximum power. This is a strong advantage of micro-inverter over string inverter.

- The advantage of a string inverter is that you only need one of them for combining many solar panels output. If anything is going to fail in a solar system it is likely to be the inverter and so there is less likelihood of servicing multiple units.

- Cost is another advantage, a single string inverter on a solar panel installation is usually cheaper than installing micro-inverters.

- The core advantage of using micro-inverters is that theoretically you can yield more solar electricity as a micro-inverter maximizes output energy at each panel level. The reason for this is that there are slight differences in voltages between solar panels. When solar panels are in a string the voltage is reduced to the voltage of the lowest voltage panel in the string.

- If a solar system is facing multiple angles, meaning some panels are facing south, some east, and some west, then micro-inverters are the way to go. Or, if you have shading issues from trees or a large chimney, again micro-inverters would be best. In these situations, the solar panels will be producing different amounts of electricity at different times of the day, but micro-inverters will ensure you harvest all of the energy, while with a standard inverter you will lose some of this production.

- Micro-inverters typically have 10 to 25 year warranties while a string inverter typically have 5 or 10 year warranties. The reliability of micro-inverters with the long warranties on the micro-inverters shows the confidence the manufacturers have in their products which is more or less equal to solar module warranties now in existence. So a user need not worry about warranty costs with micro-inverters.

- Micro-inverters offer an additional perk in system monitoring as well. A user will have the ability continuously to track the production of each individual panel, while with a string inverter you only can track the production of the whole system. This gives a user better control over solar panel warranties also.

- If you were to expand your system in the future, micro-inverters are simple to add one at a time and of any rating of solar panel prevailing at that time and can be at any location. However, with a string inverter, it would be more costly to add another full unit.

- In the long run, user has to make choice of having comparison of each of the above points against a string inverter price advantage now.

In a word: NO.

Solar is quickly becoming mainstream technology and over last 7-years or so, the price of solar panels has fallen by 80%! The biggest benefit of solar is that you can lock in years of predictable and affordable power (the sun's energy is free after all), and the biggest hurdle has been costly equipment.

With the dropping prices, more efficient permitting and installation processes plus innovations in financing – with RenXSol, solar is more affordable than ever!

Solar panels do require sunlight to make energy, however with light or intermittent clouds, your system will continue to produce energy. If there are thick, dark clouds, your system might still produce energy, but it may also temporarily shut down and automatically turn on when there is adequate sunlight.

Solar energy works great when there are cold or crisp sunny days. Of course, there are fewer hours of sunlight in the winter, but winter can be just fine for producing solar energy.