Copyright © RenXSol Ecotech 2012. All Rights Reserved

Powered by QMP

Powered by QMP

Brief Introduction to benefits of using solar energy for this purpose and simple working principle The hot air is fed into a chamber as fluidised bed or controlled atmospheric rooms where the produce is kept. Based on the design requirements, various end use applications can be designed for drying produce such as Agricultural purpose : Solar energy heated air, can be used as

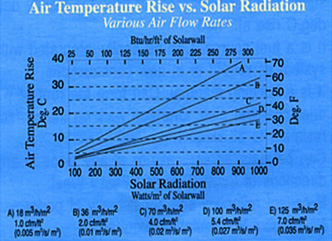

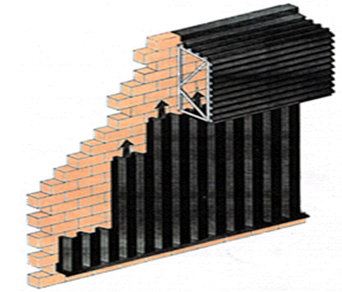

Solar food / produce / crop drying involve the use of a solar dryer designed and built specifically for this purpose. Solar drying is distinctly different from open air "sun drying," which has been used for thousands of years. A good solar food dryer dries food much faster than air drying. It can achieve higher food drying temperature, control airflow and temperature, and keep food protected while drying as well as improve the quality of the produce savings its nutrients, flavor and aromas difficult in other processes. Food Drying is a practice used to preserve fruit, vegetables and animal proteins after harvest since antiquity and a food drying unitrefers to a device that removes moisture from food to aid in its preservation. A food dehydrator uses a heat source and air flow to reduce the water content of foods. The water content of food is usually very high, typically 80% to 95% for various fruits and vegetables and 50% to 75% for various other crops. Removing moisture from food restrains various bacteria from growing and spoiling food. Further, removing moisture from food dramatically reduces the weight of the food. Thus, dryers are used to preserve and extend the shelf life of various foods. Dryers require heat using energy sources such as solar energy or electric supply or fossil fuels..Atypical dryer's basic parts usually consist of a heating source which is the sun in solar energy dryers, a fan, air vents allowing for air circulation and trays to lay produce / crop upon. The solar heated air is circulated via natural process or fans and is vented simultaneously to remove moisture from food. The produce is warmed causing its moisture to be released from its interior. The natural or forced air circulation then blows the warm, moist air out of the appliance via the air vents. This process continues for hours until the produce / crop is dried to a substantially lower water content, usually fifteen to twenty percent or less. Most foods are dried at temperatures of 130°F, or 54°C. The key to successful drying process is the application of a constant temperature and adequate air flow. Too high a temperature can cause hardened foods or lost flavor or fragrance or aromas. Also in case of vegetables or fruits or such produce, it maybe hard and dry on the outside but moist on the inside, and therefore vulnerable to spoiling, on the inside. Thus, solar heated air and such dryers provide constant and ideal temperature of hot air, without consuming conventional electricity or power enabling farmers or cooperatives or industries to obtain best quality of produce as well as saving on fuel costs. Produce / vegetables / fruits drying primarily requires heat, and solar radiation is easily converted to heat. Solar drying is effective and practical in most of the populated places of the world. RenXSol EcoTech designs employ a separate solar collector to generate the heated air, which is then directed into a drying chamber or cabinet. Thus there is flexibility of keeping solar panels exposed to the sun, while dryers can be kept elsewhere. It also provides ease of integration into existing conventional dryer already with the user. RenXSol EcoTech also has other designs wherein it can combine the collector and food / produce cabinet and allow direct heating of food. Backup electric heating or fossil fuel based heating can be incorporated into some solar dryers to provide an alternative heat source if the weather changes. Industrial Application : In cases of industries where dry or hot air is used for variety of purposes, RenXSol provides the hot air generation solar panels. Such heated air is used in processes , in incubators, in curing rooms, in poultry farms, in evaporation of toxic or unknown effluents in an economic way. The principle of hot air generation remains the same as used in above Agricultural purposes, but the application or end use of hot air can be customized. The typical principle of working of RenXSol "Solar Air Heating" process for drying or industry is shown below – The heated air temperature through solar for different volume flows can also be ascertained from the following chart –  Method of construction - The Solar Panel is mounted on the wall or roof of buildings as a wall cladding. Further insulation if required can be added. The super heating of air if required is done through additional glazing fixed on top of either polycarbonate materials or glass. The air is heated when drawn across the cross section of the solar panel "transpired collector", wherein the air collects the heat from the surface of the panel and passes through pores or minute holes on the surface of the panel to the back of the panel. Such heated air is channelized through ducts and forced through via natural chimney effect or through fans depending on air flow required to the drying chamber or area of use of the hot air.

|

|

| KSCA (M. Chinnaswamy Stadium) Watch Video |